FMW Wood Chip Handling Solutions

Journey to optimizing your profit at woodyard

The global pulp and paper machinery market is on a trajectory of growth. This increasing market trend emphasizes the importance of efficient processes in wood yards to meet the rising demands and industry standards. The key to enhancing operations within the pulp and paper industry lies in efficient wood chip handling and storage systems.

FMW Industries offers innovative and proven wood chip management solutions for the pulp & paper, energy, and chip & panelboard industries. With more than 100 chip handling references worldwide, we understand that process consistency creates process efficiencies. FMW Chip Management solutions deliver homogenized material flows to the process that result in productivity improvements.

Explore our innovative wood chip handling solutions

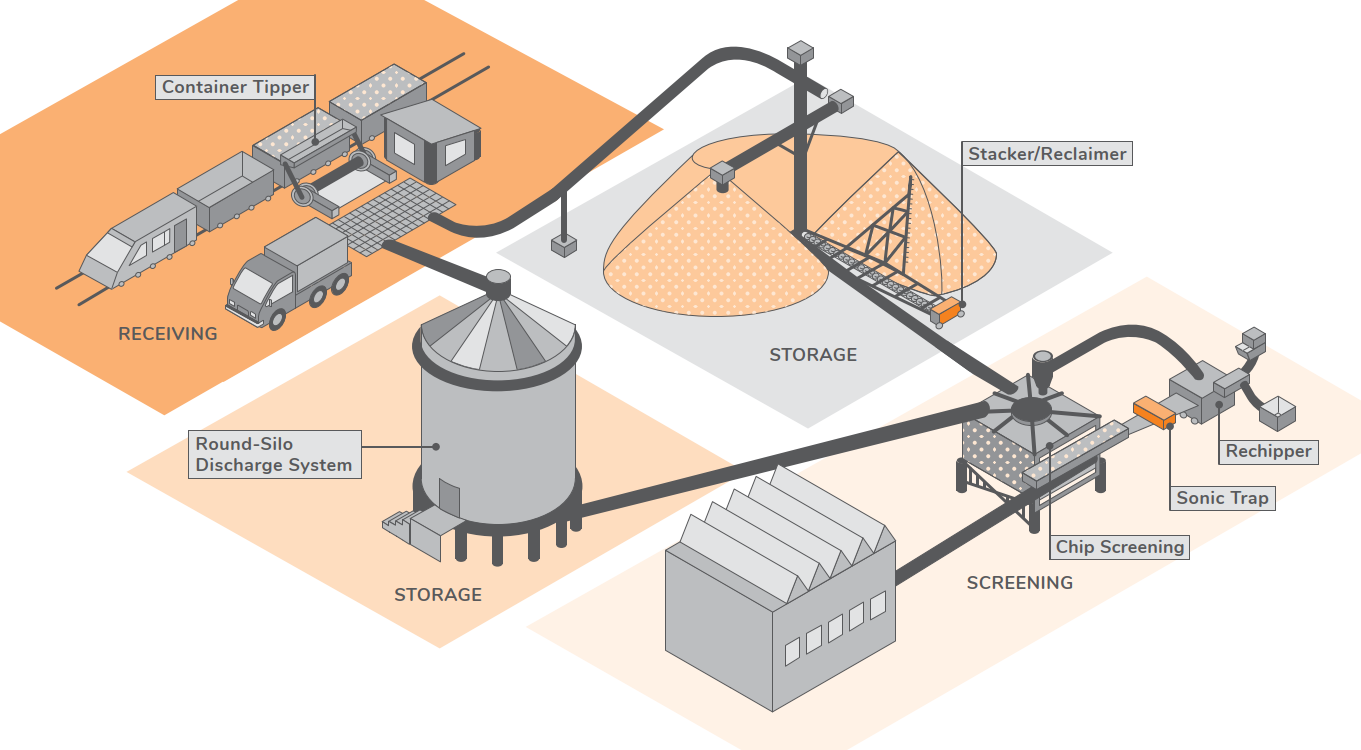

Here you will find an overview of the process steps as well as our wood chip handling solutions. We would also be happy to find the right solution together with you.

Receiving

Learn more about:

- Truck Dump

- Container Tipper

- Chain Receiver

- Stocker

- Screw Hopper

Storage

Learn more about:

Screening

Learn more about:

- Chip Screening

- Sonic Trap

- ReChipper

- Disc Screen

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Weitere InformationenFrom receiving to the digester

Our comprehensive wood chip handling systems begin with the receipt of raw material and covers all aspects of chip handling. Once received, chips enter a fully automated system designed specifically for your unique application. Conveyors (belt conveyors, air supported conveyors, screw conveyors, chain- or bucket elevators) are selected based on the requirements of each individual conveyor and chips are transported in a uniform quantity and speed. Depending on your requirements (storage capacity/covered or open system) the wood chips are transported to an FMW Blended-Bed Stacker/Reclaimer or to a Chip Silo. Components of these systems also include Truck Dumps, Screening/Re-Chipping, and Day Bins/Hoppers with metering devices. Each system is designed to ensure optimal preparation and increase productivity of the downstream process.

Fully automated first-in-first-out storage system

The Stacker/Reclaimer system is the perfect solution for all those who are looking for an efficient, proven, and gentle method for storage and reclaiming of wood chips. With its very high reliability and rugged design, this system provides a dependable solution. Also providing fully automatic operation, first-in-first-out chip inventory management, reduced chip degradation, increased wood yield, and the homogenization of chips sent to the down streaming process, this system offers the highest internal rate of return possible in a wood chip handling system. FMW’s Blended-Bed Stacker/Reclaimers have been tested and proven in more than 70 references globally since 2001.

Significant higher yields with the wood chip screening system

To enhance production efficiency, quality, and productivity, our wood chip screening system plays a vital role. It removes oversized chips and fines, ensuring only acceptable material is retained. Our FMW Screening System consists of a primary and secondary screening. The primary screen is a Disc/Scalper which separates oversized material and lumps from the chip flow, directing them to the Re-Chipper. The secondary screen is a gyratory screen and separates overs and fines from the acceptable rate. Acceptable material is transferred directly to the downstream process, while fines are collected in a fines bunker. Oversized chips pass through a metal detector and Stone Trap to remove impurities (s.a. stones, ferro and non-ferro magnetics) before being cut to the desired length by the Re-Chipper for re-screening. This efficient process boosts yield and minimizes losses in subsequent production stages.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.