FMW Plastic Bale Dewiring Solutions – Overview

Tackling the Plastic Bale Dewiring Challenge: FMW’s Efficient and Safe Solutions

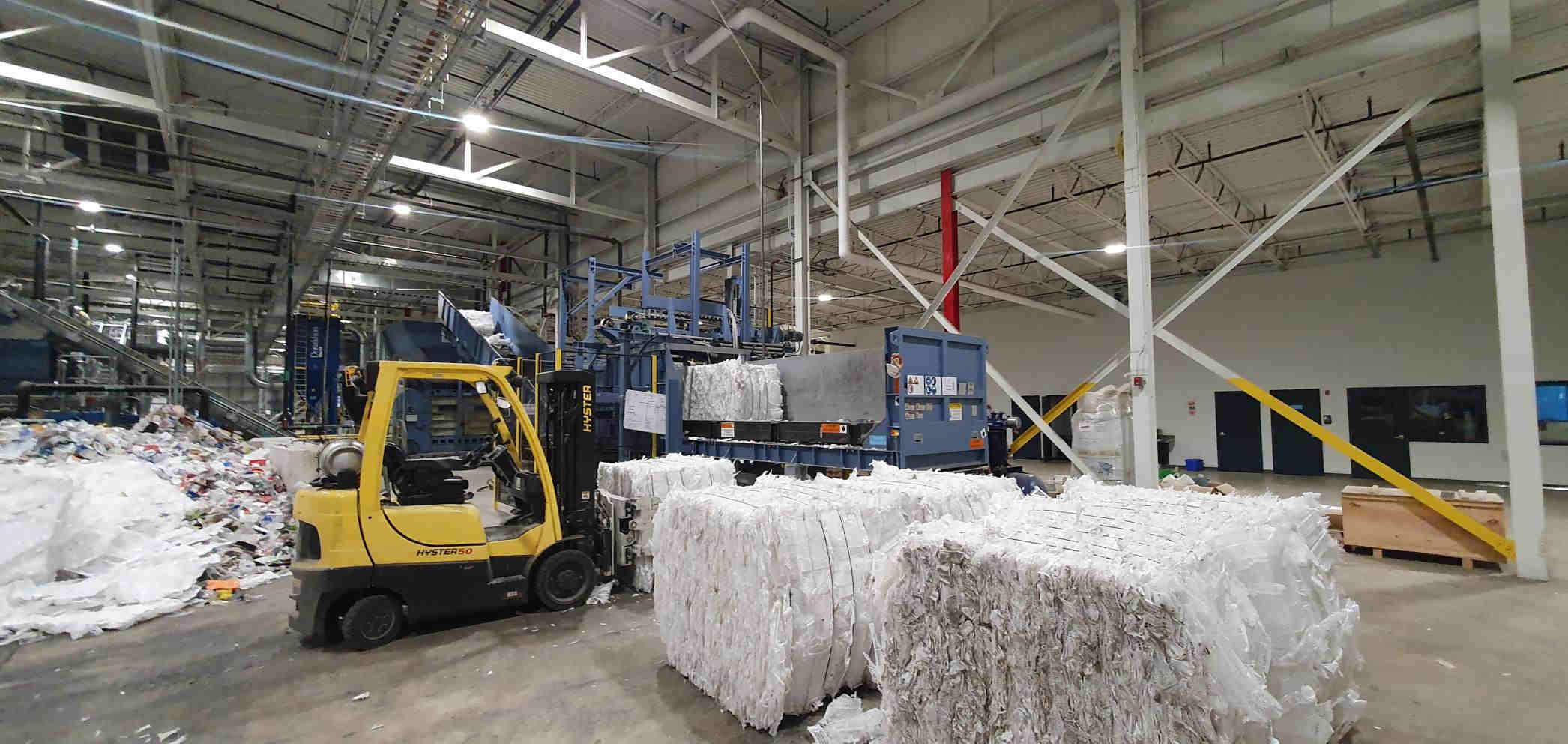

Handling and processing plastic bales in recycling facilities can be a time-consuming and labor-intensive task. The dewiring process, in particular, presents a significant challenge. It involves the removal of wires that secure the bales, ensuring that the material can be further processed without any hindrances. Inefficient dewiring not only affects the overall productivity of a facility but also poses safety risks to workers. FMW, a leading Austrian engineering company, has developed two specialized solutions to help facilities overcome these challenges: the Wire Extractor and the Cross Wire Extractor (CWE).

The global waste recycling services market continues to grow, driven by increasing environmental awareness and consumer demand for sustainable practices. The market is estimated to reach a value of nearly $90 billion by 2028, with a forecast CAGR of 4.8% from 2021 to 2030. This growth highlights the importance of efficient and safe plastic bale handling solutions, such as the ones offered by FMW.

FMW Industries’ Plastic Bale Dewiring Solutions: An Overview

Explore our advanced Plastic Bale Dewiring Solutions:

Wire Extractor: Automated Dewiring for Standard Plastic Bales

FMWs Wire Tron is designed to automatically dewire plastic bales. It’s ideal for recycling facilities handling bales with standard wiring configurations. The solution offers increased efficiency and safety, allowing for the separation of wires for recycling and ensuring that the plastic materials can be further processed without any obstructions.

Cross Wire Extractor (CWE): Specialized Dewiring for Complex Plastic Bales

The CWE is specifically designed for dewiring plastic bales with crosswire configurations, where wires run in two planes, making the removal process more complex. This solution addresses the challenges posed by such bales and is optimized for recycling operations handling intricate plastic bales.

In Summary

Key Differences and Advantages of FMW’s Dewiring Solutions

While both the Wire Extractor and the CWE offer automated dewiring solutions, they cater to different types of plastic bales. The Wire Extractor (Wiretron) is suitable for standard wired plastic bales, whereas the CWE is specialized for complex crosswire bales. By offering these two distinct solutions, we ensure that recycling facilities can choose the solution that best fits their specific needs.

The advantages of using FMW’s dewiring solutions include increased operational efficiency, enhanced worker safety, and reduced wire contamination in recycled plastic materials. These benefits contribute to the overall productivity and sustainability of recycling facilities, helping them meet the growing demand for efficient waste recycling services.

Conclusion

If your recycling facility is looking for a reliable and efficient solution to tackle the challenges of plastic bale dewiring, FMW’s Wire Extractor and Cross Wire Extractor are the ideal choices. By automating the dewiring process and ensuring worker safety, these solutions can help you optimize your operations and stay ahead in the ever-growing recycling industry. To learn more about FMW’s dewiring solutions and how they can benefit your facility, contact us today. Together, we can build a more sustainable future.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.