FMW Dewiring Solution – Automatic Plastic Bale Dewiring (CWE)

Efficient Plastic Bale Dewiring with Crosswire Configurations: Maximizing Productivity and Safety in Plastic Recycling Facilities

The recycling industry has experienced significant growth in recent years. This growth is driven by increasing environmental awareness, the need for effective waste management, and the demand for sustainable solutions. In particular, plastic recycling has become a critical focus due to the environmental impact of plastic waste and the need for efficient, safe, and cost-effective solutions in recycling facilities.

Introducing FMW CWE

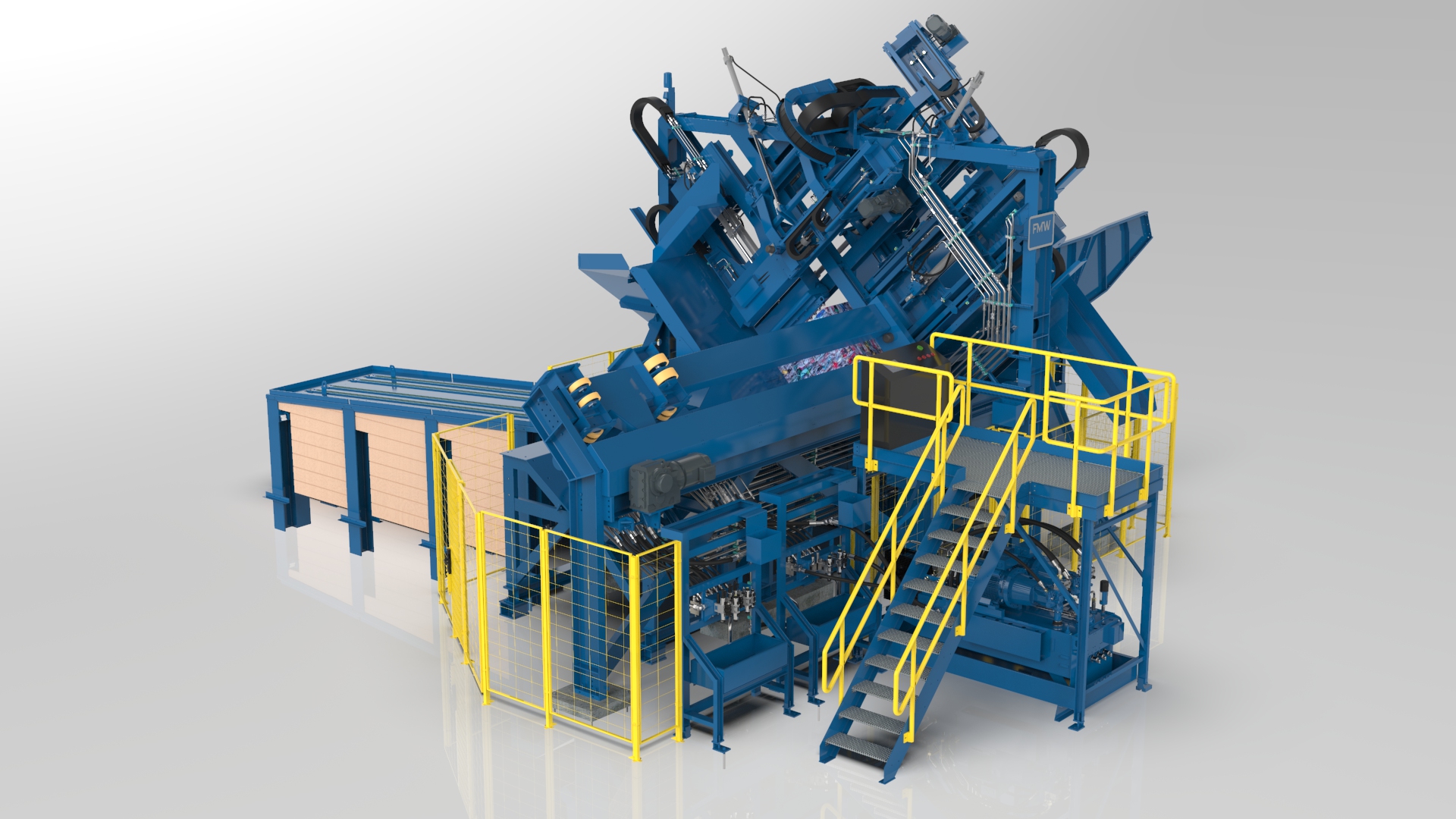

Introducing the CWE – Cross Wire Extractor, a solution designed specifically for the efficient dewiring of plastic bales with cross wire configurations. This advanced equipment maximizes productivity and safety in plastic recycling facilities, addressing the challenges faced by operations management in handling complex plastic bales.

FMW CWE minimizes wire contamination in recycled materials, ensuring a higher quality end product.

Key Features of CWE – Cross Wire Extractor

The CWE – Cross Wire Extractor is designed to automate the dewiring process of plastic bales with crosswire configurations, significantly reducing manual labor and improving worker safety. Its key features include:

- High throughput

- Improved safety

- Reduced labor in the intake hall due to automated material distribution after dewiring, resulting in cost savings and optimized resource allocation.

How it works:

The CWE – Cross Wire Extractor is designed to handle plastic bales with crosswire configurations, which are commonly used in the packaging industry. Bales are placed on the intake conveyor using forklifts with bale clamps, and the intake conveyor feeds the bales to the dewiring area. A pusher positions the bale for dewiring, where wires are clamped, opened, gripped, pulled, wound, and ejected. Loose material from the previous bale is pushed out of the dewiring area before the next bale is introduced.

Why Choose the CWE – Cross Wire Extractor

The CWE – Cross Wire Extractor is the ideal solution for recycling facilities seeking to save time and enhance worker safety when handling plastic bales with crosswire configurations. It is suitable for bales made from a variety of plastic materials and is not suitable for irregularly shaped bales or those with large surface materials that hinder dewiring. By automating the dewiring process, the CWE – Cross Wire Extractor helps reduce wire contamination in recycled materials, ensuring higher quality end products and increased customer satisfaction.

Conclusion

The CWE – Cross Wire Extractor is a game-changing solution for plastic recycling facilities handling complex plastic bales with cross wire configurations. Its innovation, flexibility, and high reliability make it the perfect choice for operations management looking to improve efficiency, reduce labor costs, and enhance worker safety. Trust FMW, your reliable partner in the recycling industry, to deliver exceptional results with the CWE – Cross Wire Extractor.

Discover more about FMWs Plastic Bale Handling Solutions.

Explore our innovative solutions designed for professionalism, innovation, and reliability. Discover more on our Plastic Bale Handling Overview page.

For further insights and tailored solutions, connect with our experts today. Your path to optimized operations and innovative solutions begins with a simple click – reach out now for more information!

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.