FMW Dewiring Solutions Overview

Enhancing Efficiency and Safety with FMW’s Dewiring Solutions

The global uncoated paper market is expected to reach a staggering $35.0 billion by 2030, with a growing emphasis on sustainability and eco-friendliness. This rapid growth is driving the demand for efficient and reliable pulp bale handling and dewiring solutions in the pulp and paper industry. FMW, a leading Austrian engineering company, offers tailor-made solutions designed to meet the specific needs of its clients while prioritizing quality, experience, and professionalism.

The Challenges of Pulp Bale Dewiring

Pulp bale handling and dewiring are critical processes in the paper production industry, ensuring the smooth and efficient transportation and processing of raw materials.

FMW Industries’ Dewiring Solutions: An Overview

FMW offers a range of pulp bale handling and dewiring solutions which are designed to optimize efficiency, safety, and productivity while minimizing labor costs and downtime.

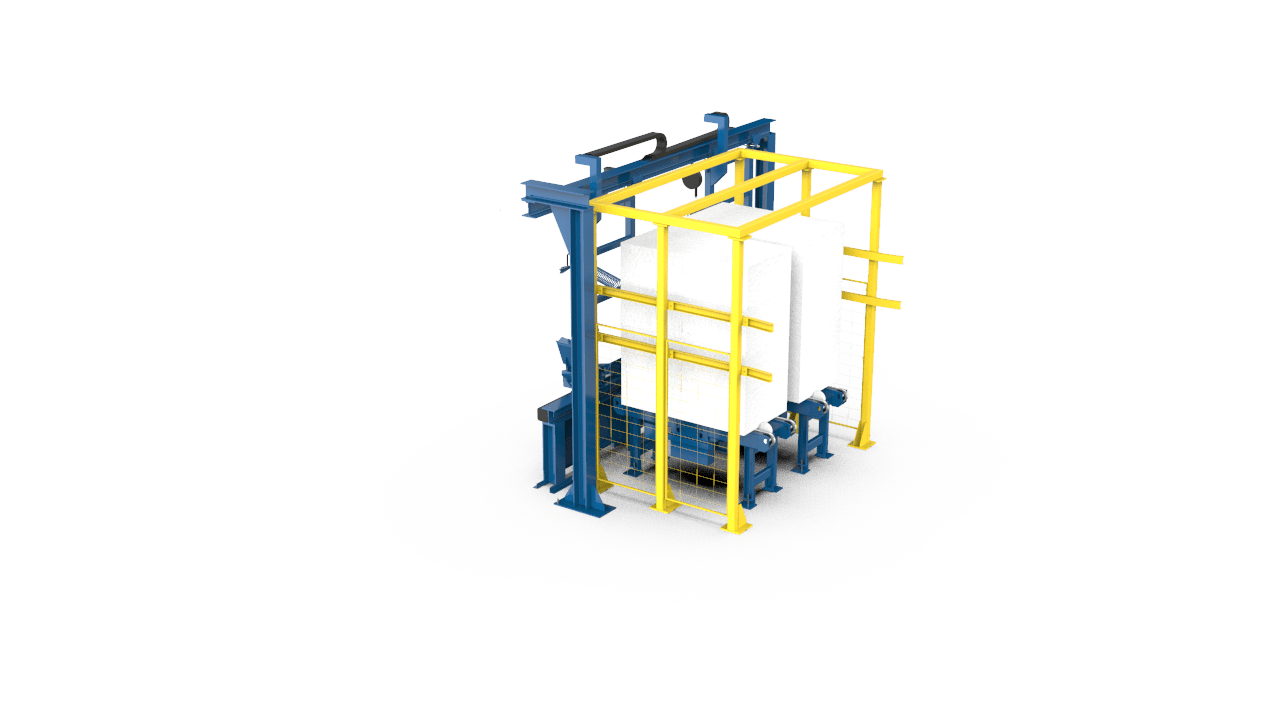

Automatic Unit Dewiring (UD 8)

FMW’s automatic unit dewiring solution streamlines the process of removing wires from pulp bales, significantly increasing throughput and reducing manual labor. This fully automated system ensures consistent and precise dewiring results, making it an ideal choice for large-scale industrial operations.

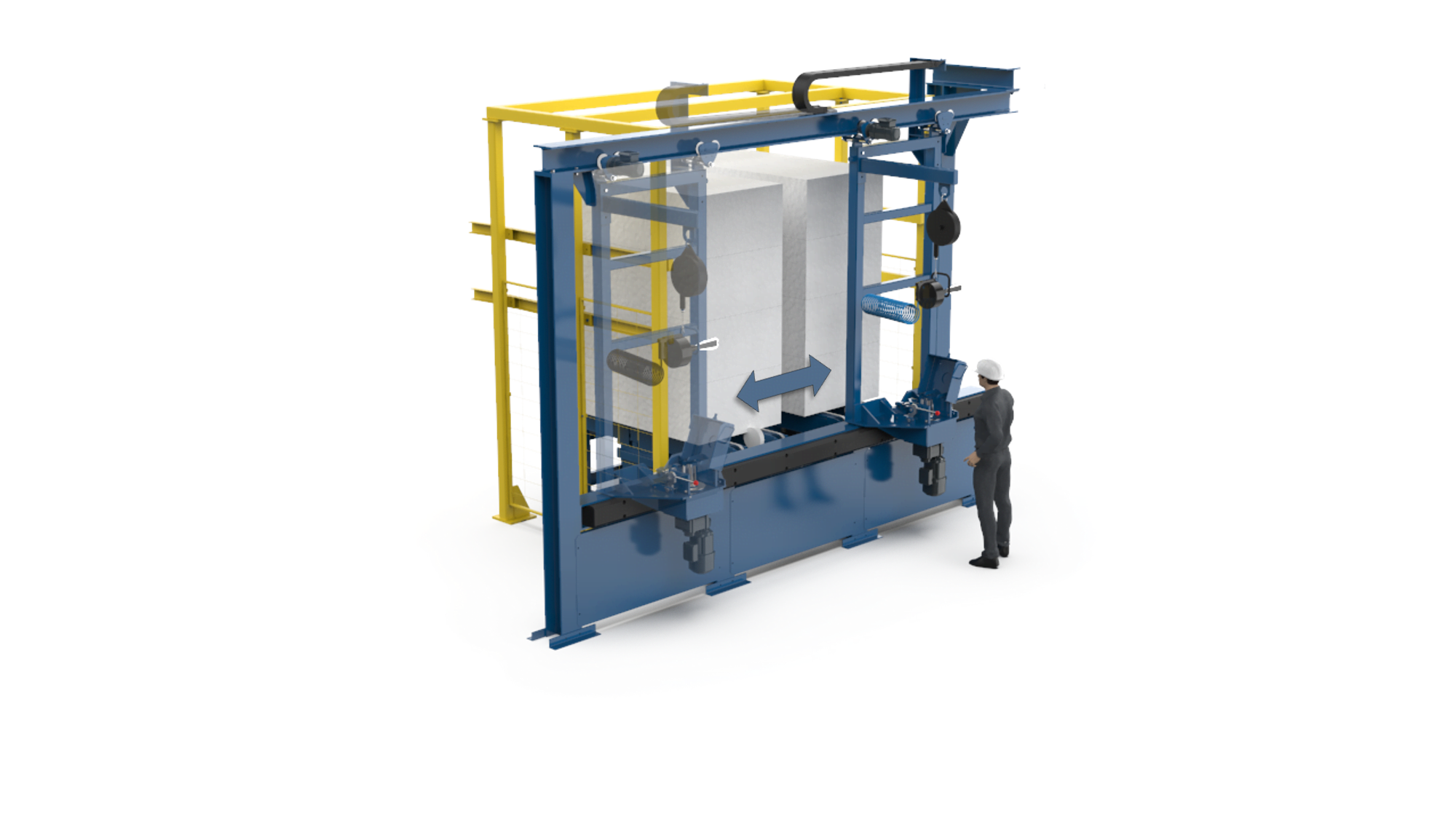

Semi-Automatic Unit Dewiring (SA 8)

The Semi-Automatic Unit Dewiring solution combines manual and automated elements, with operator involvement to assist in the dewiring process. This approach offers improved operator safety and versatility, making it suitable for medium-scale facilities.

Automatic Pulp Bale Dewiring (WireKing)

Designed specifically for the pulp and paper industry, FMW’s automatic pulp bale handling solution efficiently removes wires from pulp bales, ensuring a smooth and continuous supply of raw materials. This high-speed system integrates seamlessly with pulp processing lines and offers enhanced safety features for pulp mill operations.

Available for all Pulp Bale Sized including Domestic Bales

Manual Bale Dewiring

For smaller-scale or customized tasks, FMW’s manual bale dewiring solution relies on skilled operators to manually remove wires from pulp bales. This approach provides greater control over the dewiring process while maintaining simplicity and low upfront costs.

The FMW Advantage: Quality, Experience, and Professionalism

By choosing FMW’s pulp bale handling and dewiring solutions, clients can benefit from the company’s decades of experience, expertise, and commitment to quality. FMW’s solutions not only enhance efficiency and safety but also contribute to long-term cost savings, enabling clients to focus on their core business processes.

Conclusion

If you’re looking to improve the efficiency, safety, and productivity of your pulp bale handling and dewiring processes, consider partnering with us. Our range of customized solutions, backed by our experience and commitment to quality, ensures that you’ll receive the best possible results tailored to your specific needs.

Let’s talk about how we can help you to improve your process and contact our team of experts. We are looking forward to find the best solution for your requirements.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Engineers of progress.