FMW Wood Chip Storing Solution – Blended-Bed Stacker/Reclaimer

Introducing the FMW Blended-Bed Stacker/Reclaimer System – DAX-REX

In today’s fast-paced world, the pulp and paper industry is experiencing substantial change. This change can be attributed to factors such as rising e-commerce, sustainable packaging requirements, and the constant need for innovation. The mills are under pressure to improve efficiency, meet deadlines, and manage costs effectively.

The best place to introduce process efficiency is at the beginning, in the woodyard. The Blended-Bed Stacker/Reclaimer is an innovative and proven system, that provides efficient wood chip storage with high reliability, maintaining quality, and availability. With over 70 global references since 2001, FMW ensures high-quality Austrian engineering and reliability.

FMW’s Stacker/Reclaimer: A Fully Automated Solution for Wood Chip Storage

Efficient pulp mill operations begin at the woodyard. The FMW Blended-Bed Stacker/Reclaimer (DAX/REX) system is a fully automated operational solution with very high reliability that effectively manages your wood chip storage. Its “first-in first-out” operation guarantees a 100% active storage and reclaim volume, providing gentle treatment and perfect homogenization of incoming chips. This combination of benefits offers the highest internal rate of return possible in a chip handling system.

FMW Industries has over 70 Stacker/Reclaimer References globally since 2001.

Unique benefits of blended bed stacking & reclaiming

- Automatic “first-in first-out“ operation (no dead areas)

- Improved Chip Quality

- Perfect homogenization and blending of chips

- Low energy and maintenance costs

- Simple and heavy duty design

- Remote monitoring and remote reclaimer control

- Safety first: Reduces manual handling and operator exposure to potential hazards

How it works

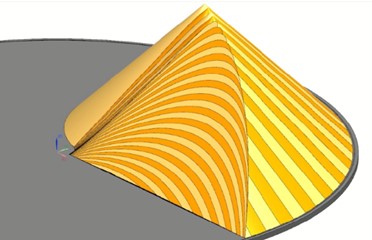

The FMW Blended-Bed DAX/REX system is a sophisticated material handling solution designed for efficient stacking, blending, and reclaiming of wood chips. This system combines the capabilities of two individual machines, the Stacker (DAX) and the Reclaimer (REX) in a single unit.

Stacking

The wood chips are transported, via conveyor, to the Stacker (DAX). The stacker rotates 360 degress in a circular fashion to create a chip pile.

For more information about storing capacities, please contact our team of experts.

Reclaiming

The reclaiming of chips is carried out on a first-in first-out basis by automatically rotating 360 degress.

The rotating reclaimer is supported by the center column, and on the outer circumference by large rubber tires moving on a concrete ring. The heart of the machine is the rake which sweeps the wood chips to achieve a constant homogenized flow at the reclaiming screw, which is located along the reclaimer boom.

The specially designed reclaimer screw gently transports the wood chip to the central hopper, which is located beneath the central column in the reclaim vault.

Low Maintenance Design

The Stacker is fixed in a horizontal position, eliminating the need for hydraulic systems or rope winches. The Reclaimer uses a central support assembly that eliminates the need for a slewing ring bearing, and the Reclaim Screw, is based on a heavy-duty design.

Why to choose a Stacker/Reclaimer System?

- 100 % Active storage volume

- 100 % First-In / First-Out Operation

- Improved Chip Quality

- Efficient & Economical Operation

- Ease of Maintenance

- Economical Total Investment

Conclusion

In conclusion, the FMW Blended-Bed Stacker/Reclaimer system offers an integrated solution for efficient stacking, blending, and reclaiming of wood chips while creating a safer working environment. Its versatile capabilities, including automated operation, blending, and remote control, make it a valuable asset in industries requiring precise material management and consistent material composition.

Contact us today to discuss your requirements and learn more about how the DAX-REX system can improve your wood chip storage process.

Discover more about significant higher yields with the FMW chip screening system.

The quality of the raw materials used directly impacts the final product quality. Wood chips, the primary raw material, need to be uniform in size and free from impurities to ensure a smooth and efficient production process. FMW Industries’ screening solutions provides a technology that effectively separates oversized chips and fines, leaving only high-quality material for further processing.

Turning Challenges into Triumphs

FMW is dedicated to providing flexible, tailor-made solutions that best meet your needs. We stand for innovation, know how, flexibility and quality. We take pride in being your trusted partner, supporting you from the initial pre-project phase through seamless on-site commissioning and After Sales & Services. We are your Egnigeers of progress.